The tech industry is at a time when it’s easy to fall into the commodity trap. Too many products and services are the same: simply a piece of hardware, software, or an API. From the end customer point of view, they just want a product to work and they want someone they can trust to take that accountability. This is why product companies develop purpose-built server appliances to deliver their software to make it simple and convenient for seamless deployment and support. Unfortunately, many software companies do not have the expertise or necessary assets to manufacture their own products: outsourcing their production then makes a lot of sense.

Choosing the right business production strategy is one of the most essential elements for success. Business production strategies fuel the ability of product companies to compete, grow and thrive in competitive markets. There are six primary strategies companies can use to guide effective decision making for production and stocking:

- Engineer-to-order (ETO)

- Make-to-order (MTO)

- Make-to-stock (MTS)

- Assemble-to-order (ATO)

- Configure-to-order (CTO)

- Chase demand

Making an informed decision for your enterprise to choose an outsourcing partner that is right for your business is impossible without understanding each of these production strategies, what the relative advantages and challenges are, and how to make relevant performance comparisons. Here’s a closer look at each of engineer-to-order, make-to-order, make-to-stock, assemble-to-order, configure-to-order, and chase demand.

Engineer-to-Order (ETO)

Engineer-to-order strategy is delivered through extremely detailed customer specifications that require unique engineering design, specialized customization, or precise materials. Each customer order results in a unique bill of materials and routing. Products are typically designed and made from scratch, where substantial amount of lead times are added to a number of engineering and analytical activities.

- Advantages include production outputs that are customized, or specialized for specifically unique requirements and environments. Sales teams are open to sell product concepts that don’t have any fixed designs and feature sets or time lines for delivery.

- Challenges include requirement for multi-disciplines in engineering processes and fields such as systems engineering, mechanics, electronics, software, and manufacturing. The adoption of product development methodologies and ongoing documentation techniques is critical to the entire engineering design and order process flow.

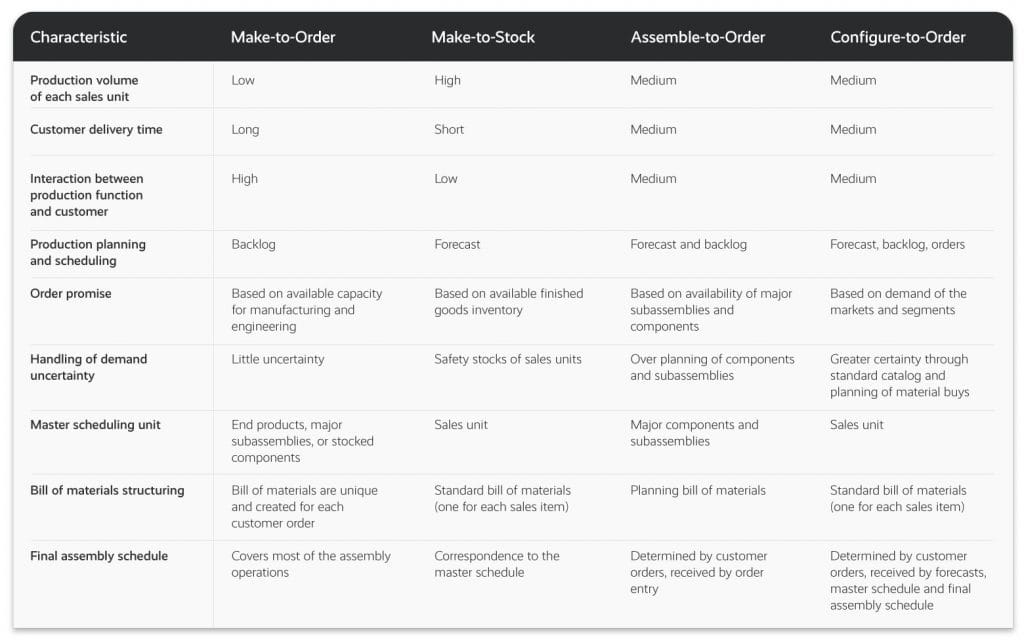

Make-to-Order (MTO)

This is perhaps the simplest business production strategy: within a make-to-order process, a customer places an order and the manufacturer makes the component or product and sends it. Design and customization is commonly part of the ordering process, enabling customers to receive exactly the output desired, and production does not commence until each order is received.

- Advantages include optimal resource cost and efficiency and high capability for custom specifications and requirements.

- Challenges include low ability to manage supply/demand, complex component inventory, supply chain management, and comparatively longer customer wait times.

Make-to-Stock (MTS)

Make-to-stock is similar to make-to-order, primarily differing in using a forecasting process to determine the timing and size of an order. The customer sets a schedule for ordering that matches their anticipated need for stock, based on sales forecasts, demand anticipation, or market expectations. The order schedule can be adjusted to match anticipated demand spikes, or smoothed to accommodate steady delivery over a given period.

- Advantages of make-to-stock include the ability to optimize resource efficiency, simplified scheduling, and minimal customer wait times.

- Disadvantages include the requirement for technically advanced and accurate forecasting data and inventory inflexibility.

Assemble-to-Order (ATO)

This business production strategy is a blend of make-to-order and make-to-stock strategies – essentially combining the benefits of each – and begins with an inventory of basic components that are already produced. Final assemblies are not executed until detailed product specifications have been confirmed from booked orders. When orders from customers arrive, they can be quickly assembled, with some minor changes or variation if required. From order to delivery, the production process prioritizes speed. Because the assembly cost is negligible, costs primarily rest within manufacturing of the components and/or material preparation.

- Advantages include low overhead for inventory storage, flexibility to accommodate some customization, minimal inventory carrying costs, and lower risk of unsold inventory.

- Challenges include the problem that low inventory creates risk of low sales and comparatively longer lead time for production. It is suited for products that have expanding demand volume and similarity. Wider variety of products may lead to issues with forecasts, scheduling, material management, and overstocking.

From ATO to Configure-to-Order (CTO)

Configure-to-order is a strategy that utilizes design selection at the time of order to allow additional flexibility within the production process and enables more customizable options to their end customers. The company sets up and orders from its pre-defined standard catalog of components and specifies the product features, values or parameters. Procurement of subassemblies and components are performed before the sales order is received, and production is performed after the sales order is received. Inventory replenishment is driven at the component level and not at the finished good level. Final product assembly is delayed until the sales order arrives, which provides the flexibility for the product variations. A major difference between ATO and CTO is in inventory and stocking levels required to enable customers to ‘pick’ the order from a configuration list of options.

- Advantages include improved scalability, flexibility, and enhanced specialization of output, reduced inventory and storage costs, and compressed cash cycle. Configure-to-order is an excellent business production model that provides mass customization and quicker order fulfillment. Maintaining and sourcing inventory only when an order arrives keeps manufacturers stress-free from cash that is tied up in excess inventory.

- Challenges include the need for additional data resources and program management from both parties to optimize planning. Sophisticated ordering, inventory and material planning systems are needed to onboard the configure-to-order program. The potential need to define service level agreements to manage demand variance could require some time to sort out. Expect to hold more in inventory and safety stock than compared to the assemble-to-order strategy.

Chase Demand

Chasing demand is the business strategy that leaves the most to chance. Production is set solely by price demand in the market and from customers. When demand goes up, resources are added to increase production; when demand declines, resources are throttled back to ensure inventory does not outstrip orders. This strategy requires built-in flexibility, to quickly and efficiently accommodate demand and supply variation.

- Advantages of chasing demand include low requirement for inventory management and costs, and typically favorable customer wait times when promised.

- Challenges include being completely at the whim of the market, difficulty in managing both inventory and pricing, and difficulty in managing variable resource requirements. Since this strategy leaves everything to chance, the management team must have high confidence levels in data, robust controls, and an appetite for risks.

Making the Right Business Production Strategy Choice

In general, consider the following advice for choosing a production and stocking strategy:

- ETO is recommended for enterprises that specialize in a field or industry that is in a phase of innovation or early adoption where engineering and product specifications are still fairly unknown. ETO can also be applied to enterprises that are trying to rejuvenate products at an end-of-life stage.

- MTO is a recommended strategy when your product catalog is comparatively complex and you’re choosing from a large roster of customizable feature and variations. It’s well suited for producing fixed products in batch quantities.

- MTS is a more appropriate strategy when your catalog is low in complexity and does not demonstrate significant variation between orders. Quick ship and order promise is the main concern.

- ATO is ideal for enterprises that are white labeling or producing a range of products built from similar components. Choose ATO when you have a large number of sub-assemblies that can be put together quickly to create a final product. It works well when you have relatively small numbers of input products that go into a large number of finished goods.

- CTO is best suited if you have support from advanced analytics tools and fully understand your market and supply chains. You need to perform forecasting at both the assembly level and the finished goods level. Since CTO is also a combination of ATO and MTS strategies, make certain you confirm processes that help you manage order quantities, stock liabilities, and service level agreements when choosing a CTO strategy.

- Chasing demand is ideal for enterprises that have the superb flexibility required to adjust their need for resources, including workforce. Choose this strategy when price sensitivity and short-term earnings is the main concern.

Big data inputs, market analysis, demand strategy tools, supply chain and partner management systems are all tools that can be used to make an informed decision about your best business production strategy. The key is making a commitment to bring all those resources together and deploy them in support of your enterprise goals.